Direct on-Line start is probably the simplest and traditional type of start and it is to connect the motor directly to the power supply performing therefore a full-voltage start-up.It is often abbreviated with the acronym DOL.

DOL (Direct on Line) start is the simplest and most cost-effective system for starting pumps and motors and it is traditionally the most widely used. The induced current is the rotor is high. This results on a peak current on the network which can be 5 to 8 times the nominal current.

They are suitable for startup of small submersible pumps, deep well pumps or booster sets with surface pumps. DOL control panels need a direct connection to the power supply network, which implies:

• Start at full voltage and constant frequency

• High starting torque

• Very short acceleration times.

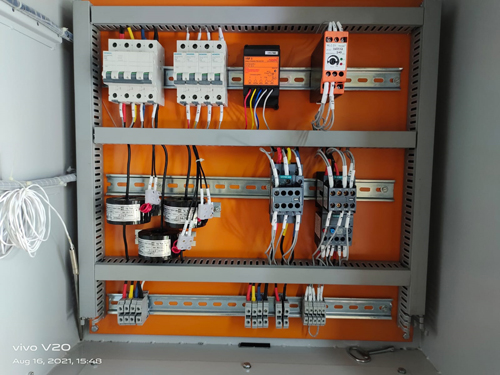

Star Delta starting is the best known and perhaps the most widely used low voltage starting method. It is used to start the pump's motor with lower levels of mechanical stress and with current limitation during start-up; it does this with the aid of a timed system which switches the control contractors installed inside the panel.

Star-delta starting reduces starting current and torque to values of 33% (1/3) of those measured during direct starting. During start-up, the currents flowing through components are lower than the motor's related current.

Application |

Specification |

Supply Voltage: |

3 Phase, 4 Wire, 440V AC, 50Hz + Earthing provision |

Rated HP: |

0.5HP to 100HP |

Rated Insulation: |

1100 V |

Ambient Temperature: |

45 Deg C |

Degree of Protection: |

IP42, IP45, IP55 |

System Protection: |

Single Phasing, Overload, Short circuit, water level |

Type Tested: |

Megger Test, HV Test |

Bus Bar (EC Grade): |

Aluminium, Copper with colour coded Heat shrink sleeve |

Switchgear: |

Schneider, Siemens, L&T, Legrand, C&S, Eaton |

Mounting: |

Base Frame, Stand, Wall Mounting |

Cable Entry: |

Top, Bottom, side |

Fabrication: |

1.6/2.0 mm thick CRCA sheet metal, standard Heavy duty Door Hinges, 7 tank Process powder coating, colour: Red (As per ISI), Dust proof Gasket. |

Termination: |

Termination space according to Ampere Rating, 2.0/3.0 mm thick Gland plate with Gasket. |

A water level control panel is a system that manages water levels on a variety of systems such as water tanks, pumps and swimming pools. The basic function of a water level controller is to regulate water flow and optimize system performance. Advantages of these panel is save water, save Energy, Maximise water and it work automatically.